SLA Printing – Benefits of Stereolithography Services

As a pioneer in the Dutch 3D printing industry, VRT has been providing leading SLA print services for almost 28 years. We distinguish ourselves by exclusively working with high-quality industrial printers, rather than the more common filament printers that now flood the market.

What is the SLA technique?

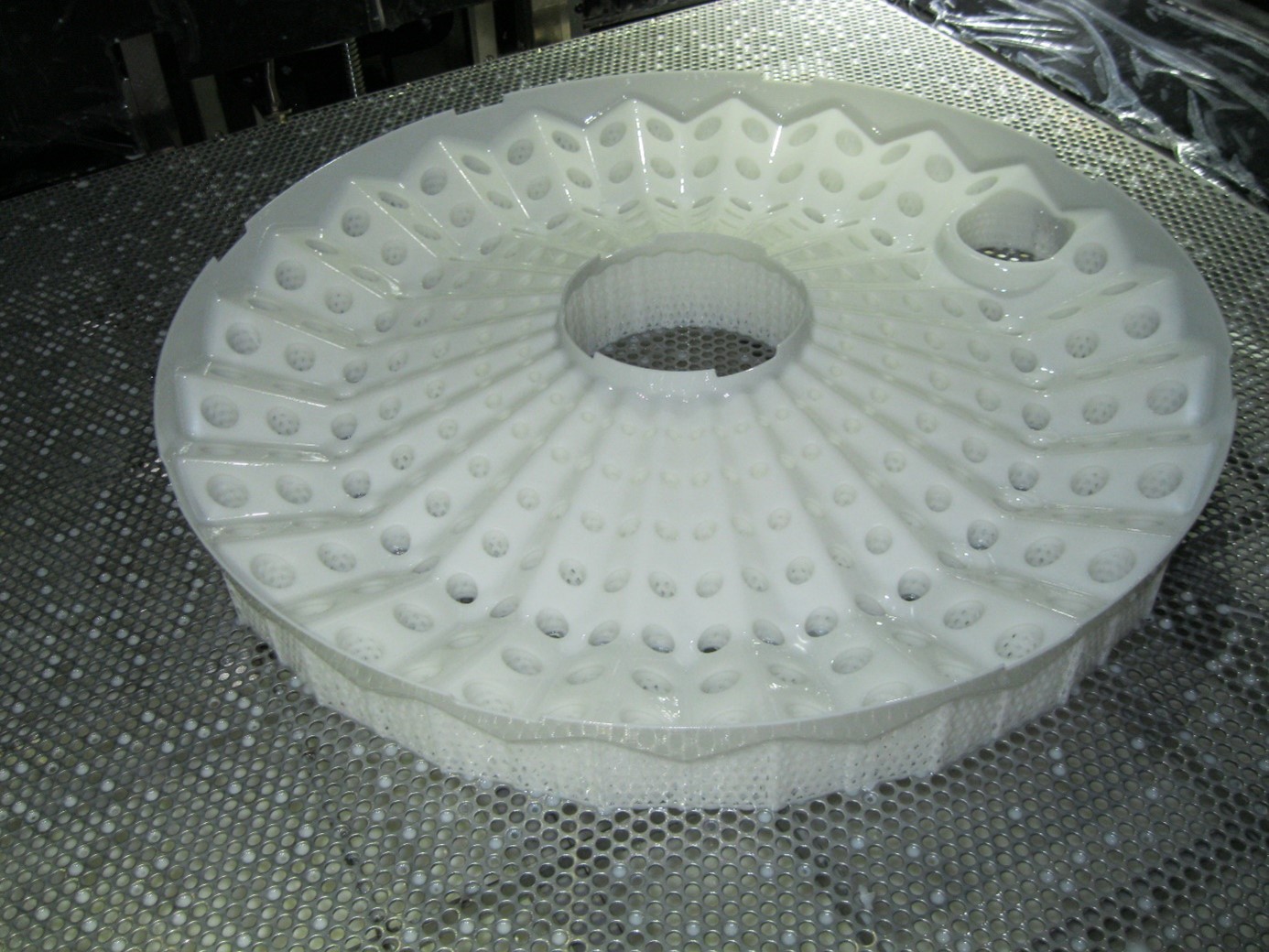

Stereolithography (SLA) is one of the oldest and most precise 3D printing techniques. It belongs to the vat polymerisation category where liquid photopolymer resin is cured by targeted light energy. SLA is characterised by its excellent detail reproduction and the smooth surface finish of the printed objects.

How does SLA printing work?

In the SLA printing process, a UV laser is used to selectively cure liquid photosensitive epoxy resin. The process works according to the following principle:

- A platform is placed in a tank with liquid photopolymer resin

- A UV laser, controlled by computer-guided mirrors, projects the pattern of the first layer onto the surface of the resin

- Where the laser touches, the resin immediately hardens and adheres to the platform

- After curing a complete layer, the platform descends 0.1mm (or the set layer thickness) deeper into the resin tank

- A wiper glides over the surface to distribute the resin evenly for the next layer

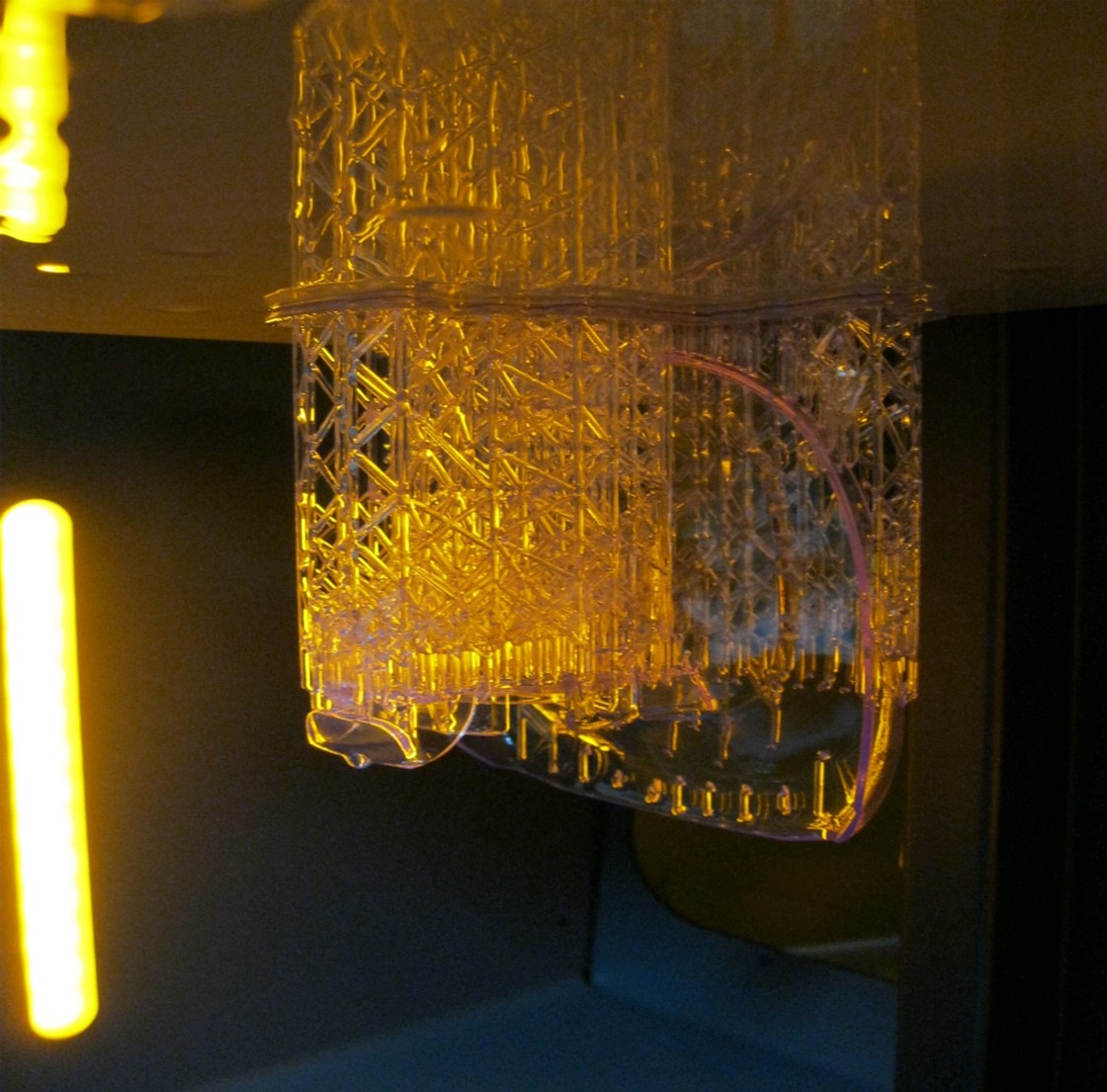

- This process repeats layer by layer until the entire object is built

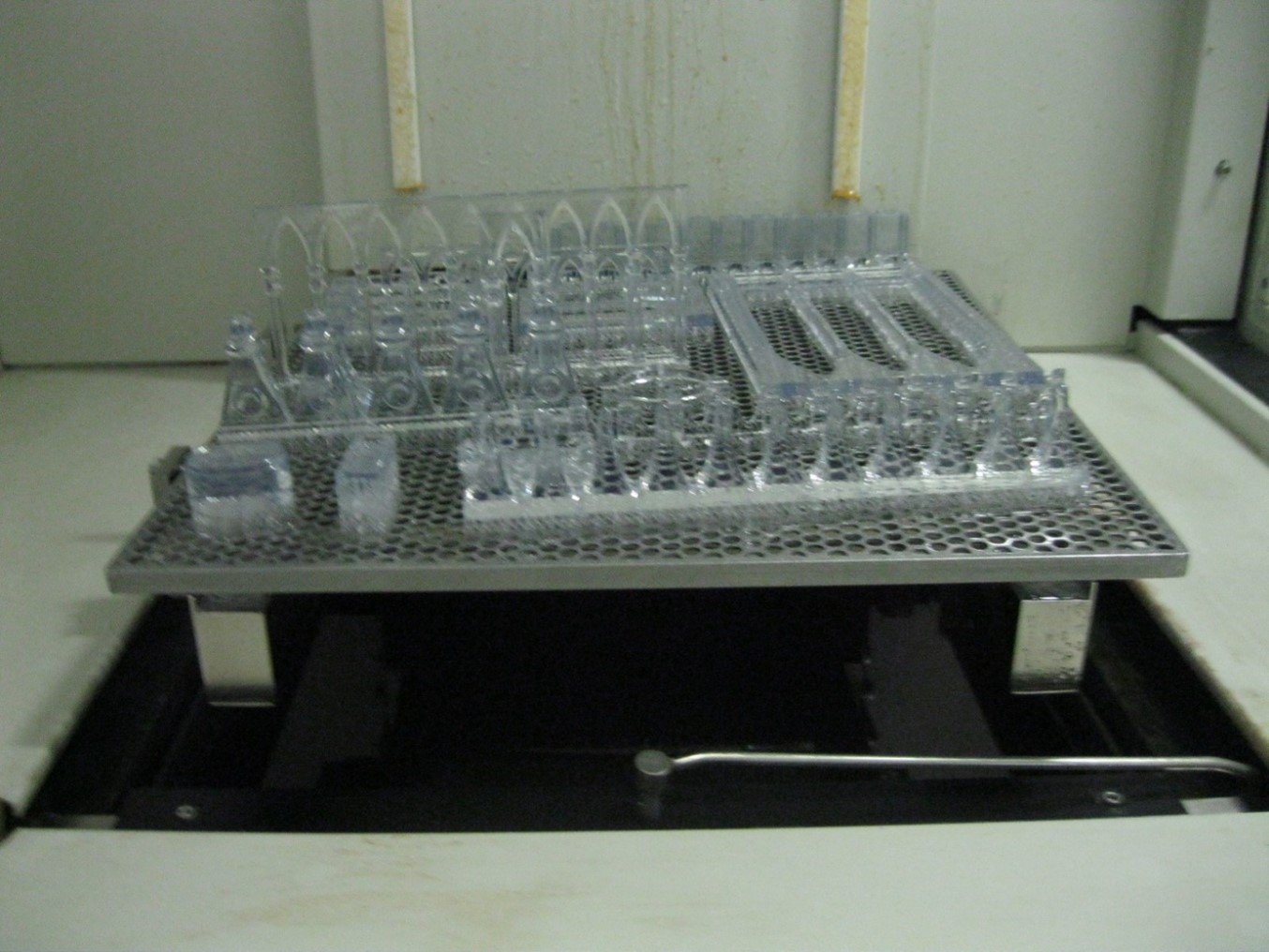

The platform can produce multiple parts simultaneously, but stacking is not possible because all objects are built on the same platform. After printing, the objects must be cleaned of excess resin and fully cured in a UV post-processing chamber.

Benefits of SLA printing

SLA technology offers numerous advantages that make it an excellent choice for high-quality 3D printing projects. The main benefits are:

- Exceptional accuracy with details down to 0.1mm

- Very smooth surfaces without visible layer lines

- Ability to print large formats without distortion

The excellent detail reproduction for complex geometries makes it possible to realise intricate structures that are difficult to achieve with conventional manufacturing methods. Additionally, SLA-printed objects are suitable for both prototypes and functional end products.

- Consistent mechanical properties in all directions

- High dimensional accuracy for fitting parts

- Waterproof prints without post-processing

This combination of properties makes SLA printing ideal for applications where aesthetics, functionality and precision are crucial.

What are the disadvantages of 3D printing with SLA?

While SLA offers many advantages, the technology also has some limitations. The most notable disadvantages are:

- Supports are necessary: SLA printing requires support structures that must be removed after printing, which requires additional post-processing

- UV sensitivity: Unpainted parts can yellow over time due to UV light

- Temperature resistance: Standard epoxy resins have a relatively low HDT (Heat Deflection Temperature), usually between 46°C and 58°C

- Always needs post-processing: After printing, cleaning, UV post-treatment and often manual finishing is required

- Limited flexibility: After printing, cleaning, UV post-treatment and often manual finishing is required

- Relatively higher costs: Compared to FDM technology, the material and machine costs are higher

SLA machines and materials

We have an impressive machine park with various SLA printers for every size project:

| Dimensions (mm) | Material | Application |

| 450x450x400 | VRT-Clear | Transparent parts and lost metal casting (best burn-out resin) |

| 600x600x450 | VRT-Somos-GP-Plus | Rigid and strong parts in yellow/white colour |

| 850x850x500 | VRT-White | Flexible functional parts in yellow/white colour, ideal for snap connections |

| 1000x1000x600 | VRT-Somos Ledo | Flexible and durable parts for Rapid Manufacturing of small series |

Mechanical properties of SLA materials

The material properties of SLA-printed objects vary depending on the resin used:

- Tensile strength (ASTM D638): From 30 to 60 MPa, depending on the material

- Elongation at break (ASTM D638): From 6% to 20%, for different flexibility requirements

- Flexural strength (ASTM D638): From 50 to 83 MPa for structural applications

- IZOD Impact (ASTM D256): Varying from 23 to 70 J/m for different impact resistance

- HDT at 0.455 MPa (ASTM D648): Temperature resistance from 46°C to 58°C

Why choose our SLA print service?

Over 28 years of experience and expertise

As the first 3D print service company in the Netherlands, we have unparalleled expertise in stereolithography technology. We know all the possibilities and limitations, allowing us to always provide the best advice for your specific application.

Honest and reliable advice

We don't sell empty promises. Our advisors provide honest advice about what is and isn't possible with SLA technology, including the advantages and disadvantages for your specific project.

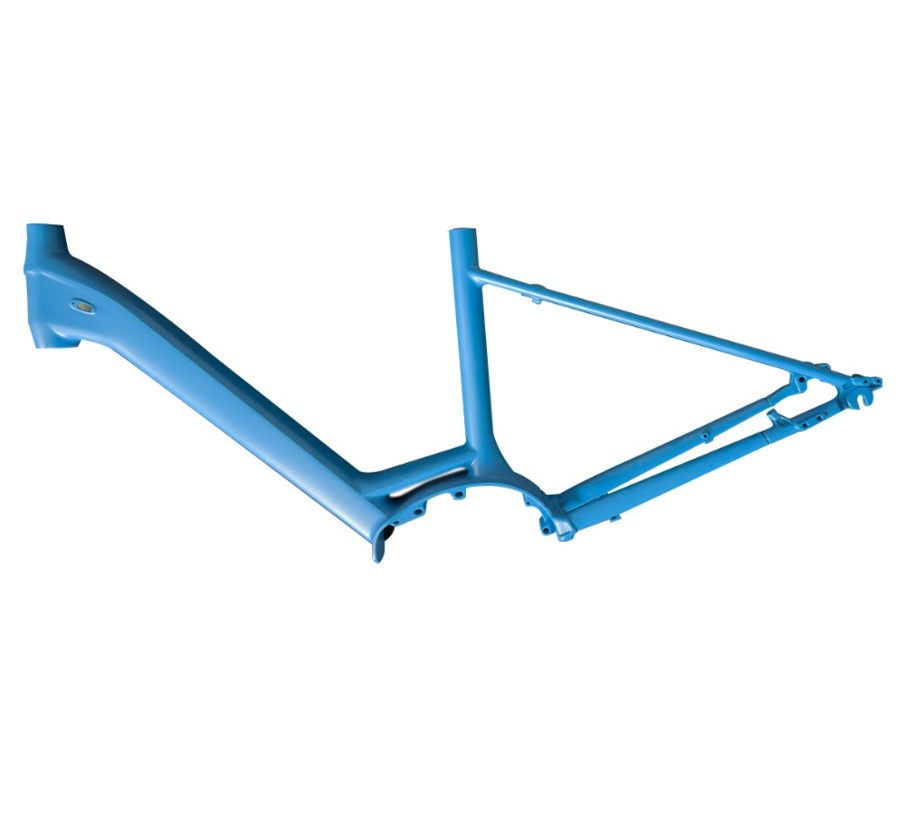

Complete service from design to finishing

Beyond printing, we offer comprehensive services covering all aspects of product realisation. We provide professional finishing and painting according to specifications, produce small series, perform additional processes such as milling from plastics, and support injection moulding with low mould investments. This end-to-end approach enables you to go from concept to final product with just one reliable partner.

Reliable partner for presentation models

We regularly deliver high-quality exhibition and presentation models that perfectly represent your product or concept.

Application areas for SLS 3D printing

SLA technology is particularly suitable for various applications:

- Functional prototypes with accurate details for evaluation and testing

- Presentation models with high-quality surface finish

- Moulds for silicone casting and other casting processes

- Master models for lost wax casting in the jewellery industry

- Small production series of complex components

- Medical models for visualisation and surgical planning

- Medical models with fine details and structural elements

- Dental applications such as braces and aligners

Contact us for your project

Would you like to know more about our SLA print service or do you have a project you'd like to discuss? Contact us for a no-obligation consultation. As a European service provider, we respond quickly, think flexibly and deliver locally with short lines of communication.

Discover why leading companies have trusted our SLA printing expertise for almost 28 years. Choose quality, experience and reliability.

Adress

Venture Rapid Technologies B.V.

Ambachtsweg 4, 5683 CD

Best, North Brabant

Send us a message

info@vrt.nl

Call us

+31 499 330774