CNC Milling –

Precision and versatility

in machining Technology

As a pioneer in the European manufacturing industry, VRT has been offering professional CNC milling and turning services for nearly 28 years. We distinguish ourselves by working with advanced 3-axis and 5-axis CNC milling machines that enable us to produce precision parts from high-quality plastics and metals.

What is CNC milling?

CNC milling is a subtractive manufacturing process where material is precisely removed using computer-controlled rotating cutting tools. This technique is one of the most versatile machining methods for creating complex components from plastic or metal. CNC milling stands out for its ability to produce accurate products with excellent surface quality and tolerances.

How does CNC milling work?

In the CNC milling process, cutting tools are controlled with high precision by a computer. The process works according to the following principle:

- A digital 3D model or 2D drawing is converted to G-code through CAM software

- The base material (plastic or metal) is securely fixed in the milling machine

- Computer-controlled milling heads selectively remove material according to the programmed path

- Different tools are automatically exchanged for various operations

- The workpiece undergoes multiple processing steps, from rough to fine

- Any complex contours are achieved through 3D, 4D, or 5D movements

With modern 5-axis milling machines, we can create complex shapes with undercuts that would be impossible with conventional 3-axis machines. This offers unprecedented design freedom for your project.

Benefits of CNC milling

CNC milling offers an excellent balance between accuracy, flexibility, and material choice freedom. The technique is known for precision and quality.

The main benefits include:

- Exceptional accuracy – Tolerances down to 0.01 mm possible for critical components

- Wide range of materials – From various plastics (PC, Nylon, PP, POM, ABS) to metals (aluminium, steel)

- No mold costs – Direct from CAD model to end product without expensive tooling

Additionally, CNC milling offers excellent surface quality, possibilities for complex undercuts, and the freedom to quickly adapt designs without high costs. This combination makes the technique ideal for prototypes, small series, and complex components.

What are the applications of CNC milling?

CNC milling is particularly versatile and can be applied for various purposes:

- Prototyping – Rapid realization of functional prototypes in the final material

- Small to medium batches – Economically viable production without mold investments

- Complex components – Realization of parts with complex geometries

- Precision parts – Products with high dimensional accuracy for critical applications

- Custom components – Bespoke parts for specific projects

CNC milling versus other techniques

CNC milling versus 3D printing

Where 3D printing excels in creating complex internal structures and lightweight components, CNC milling offers superior surface quality and accuracy. CNC milled parts have consistent material properties without the anisotropy that often occurs in printed objects. Furthermore, a wider range of high-quality materials is available for CNC milling. For precision components where dimensional stability and surface quality are crucial, CNC milling is often the better choice.

CNC milling versus injection moulding

CNC milling distinguishes itself from injection moulding by the absence of mold costs and the flexibility to implement rapid design changes. While injection moulding becomes economically advantageous for larger series, CNC milling remains the preferred technique for small series, prototypes, and complex geometries. CNC milling is also immediately available with typical lead times of 2 weeks, while injection moulding has a longer lead time for mold development. For small series or components with frequent design changes, CNC milling offers clear advantages.

CNC machines and materials

We have advanced CNC equipment for projects of any complexity:

| Capacity | Machines | Applications |

| 3-axis milling | Modern CNC milling machines | Standard components and flat machining |

| 5-axis milling | Advanced 5-axis milling centers | Complex 3D shapes and undercuts |

| CNC turning | Precise CNC lathes | Rotationally symmetrical components |

Our material portfolio encompasses a wide spectrum of plastics and metals:

Plastic CNC milling

- PC (Polycarbonate) – Transparent, impact-resistant, and heat-resistant

- Nylon (PA) – Strong, wear-resistant, and self-lubricating properties

- PP (Polypropylene) – Chemical resistant and suitable for hinged parts

- POM (Polyacetal) – Excellent dimensional stability and low friction

- ABS – Strong, rigid, and easy to machine

Aluminium CNC milling

- Aluminium 6061/6082 – Excellent machinability and corrosion resistance

- Aluminium 7075 – High-strength alloy for aerospace and automotive applications

- Anodised aluminium – With various surface treatments and colour options

Steel CNC milling

- Stainless Steel 304/316 – Stainless steel for applications with high corrosion resistance

- S235/S355 – Structural steel for structural components

- Tool steel – For components with high wear resistance

CNC services

We offer various specialist CNC services that meet your specific needs:

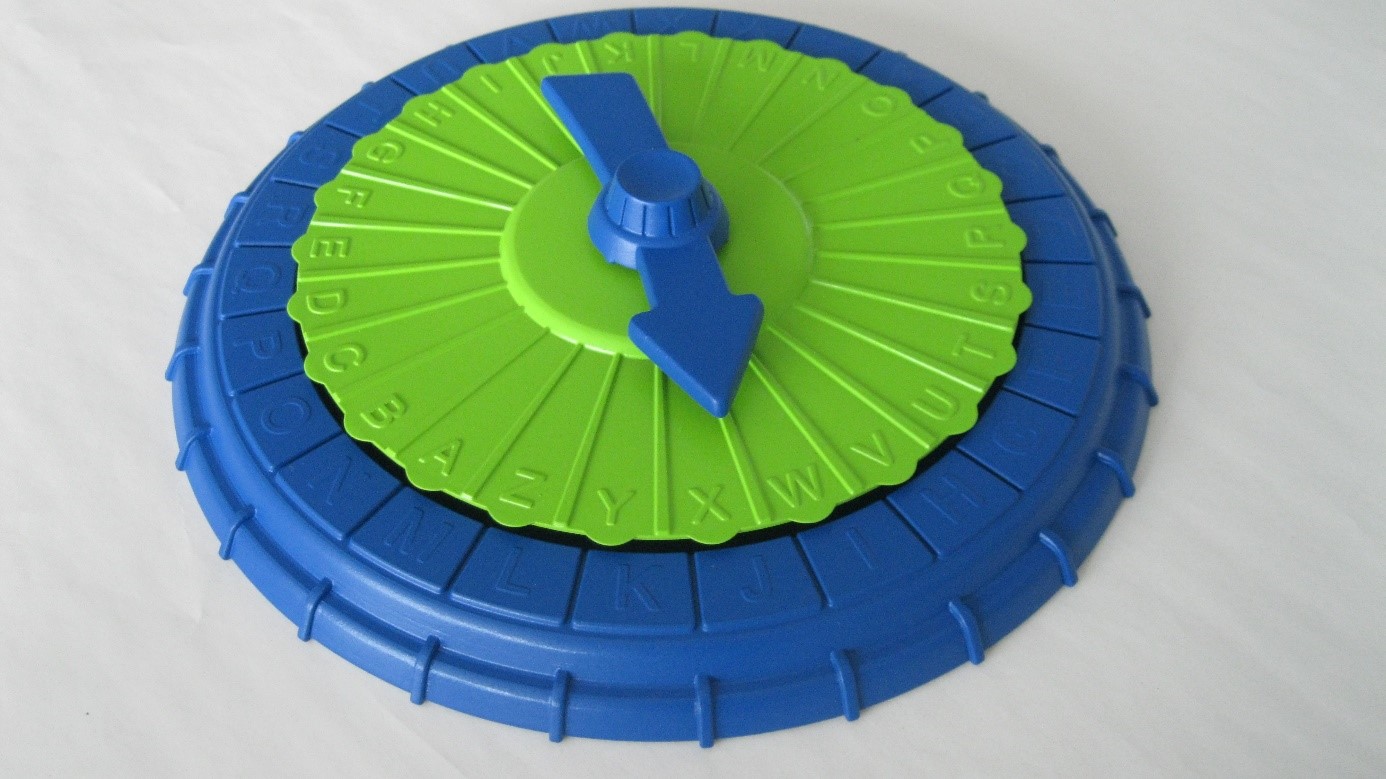

3D CNC milling

For complex three-dimensional geometries, we deploy our 5-axis milling machines. These make it possible to completely machine parts in a single setup, resulting in higher precision and shorter lead times. Ideal for complex molds, tools, and organic shapes.

Aluminium CNC milling

With our expertise in machining high-quality metals like aluminium and steel, we can produce components that meet specific functional requirements. From lightweight structural parts to components with specific mechanical properties, we deliver precision parts for various industries.

Plastic CNC milling

Our expertise in machining high-quality plastics such as PC, Nylon, PP, POM, and ABS allows us to produce components that meet specific functional requirements. From transparent components to parts with specific mechanical properties, we deliver precision components for various industries.

Why choose our CNC milling service?

Nearly 28 years of experience and expertise

As an established player in the Dutch manufacturing industry, we have extensive expertise in CNC machining technology. We understand all the possibilities and limitations, allowing us to always provide the best advice for your specific application.

Honest and reliable advice

We don't sell empty promises. Our advisors provide honest advice about what is and isn't possible with CNC milling, including the advantages and disadvantages for your specific project. This transparent approach helps us avoid disappointments and ensures you have realistic expectations of the end result.

Complete service from design to finishing

In addition to CNC milling, we offer a comprehensive service that covers all aspects of product realization. We support the optimization of your design for machining, perform various post-processing operations such as surface treatments and assembly, and can guide the transition to series production if necessary. This end-to-end approach allows you to go from concept to end product with just one reliable partner.

CNC milling costs

The costs for CNC milling are determined by multiple factors:

- Design complexity – More axes and processing steps increase costs

- Material type and quality – Different materials have different machining costs

- Dimensions and quantity – Larger parts and smaller quantities increase the unit price

- Tolerances and finish grade – Higher precision requires more machining time

- Lead time – Standard delivery time is approximately 2 weeks

For an accurate cost estimate, please contact us without obligation. We're happy to prepare a customized quote for your specific project.

Contact us for your project

Would you like to know more about our CNC milling service or do you have a project you'd like to discuss? Contact us for a free consultation. As a Dutch service provider, we respond quickly, think flexibly, and deliver locally with short lines of communication.

Discover why leading companies have trusted our CNC expertise for nearly 28 years. Choose quality, experience, and reliability with Venture Rapid Technologies.

Adress

Venture Rapid Technologies B.V.

Ambachtsweg 4, 5683 CD

Best, North Brabant

Send us a message

info@vrt.nl

Call us

+31 499 330774