SLS 3D PRINTING benefits of selective laser sintering services

As pioneers in the European 3D printing industry, VRT has been offering leading SLS print services for nearly 28 years. We distinguish ourselves by exclusively working with high-quality industrial printers (investments starting from €100,000), rather than the more common filament printers that now flood the market.

What is the SLS technology?

Selective laser sintering (SLS) is an advanced 3D printing technique in which a laser melts polymer powder into a solid object. It belongs to the powder bed fusion technologies and stands out for its ability to produce strong, functional parts without support structures. SLS 3D printing results in durable nylon components with excellent mechanical properties.

How does SLS printing work?

SLS printing uses a powerful laser to selectively melt polyamide (nylon) powder. The process follows these principles:

- A thin layer of powder is evenly spread across the build platform

- A laser, controlled by computer-guided mirrors, selectively melts the powder according to the pattern of the first layer

- Where the laser touches, the powder melts and fuses into a solid material

- After completing a layer, the platform lowers by 0.1mm (or the set layer thickness)

- A new layer of powder is spread across the surface

- This process repeats layer by layer until the entire object is built

The build chamber is heated and filled with nitrogen (N₂), which means heating and cooling time is required in this process. After printing, the parts are removed from the powder bed and sandblasted to remove excess powder, followed by any post-processing required.

Benefits of SLS 3D printing

SLS printing offers numerous advantages that make it an excellent choice for both prototyping and small-scale production. A key benefit is that no support structures are needed, as the surrounding powder serves as natural support. The process delivers strong nylon parts with excellent mechanical properties that are consistent in all directions.

The technology makes it possible to create complex geometries without limitations, including internal structures and channels that would be impossible with traditional manufacturing methods. Moreover, multiple parts can be stacked on top of each other during printing, increasing efficiency.

Other important advantages include:

- Living hinges are possible, ideal for functional assemblies

- Assembled parts can be printed in one go

- Flame-retardant materials available for specific applications

This combination of properties makes our SLS print service ideal for applications where functionality, durability, and design freedom are crucial, especially in rapid manufacturing of small to medium-sized series.

What are the limitations of SLS 3D printing?

While SLS offers many advantages, the technique also has some limitations:

- Challenging finishing: The surface is naturally porous

- Warping can occur with large parts: Deformation may happen with large, flat components

- Impregnation required for painting: Porous surfaces must be pre-treated

- Limited colour options: Powders are available in a limited colour palette

- Heating and cooling time: The process requires time for heating and cooling the build chamber

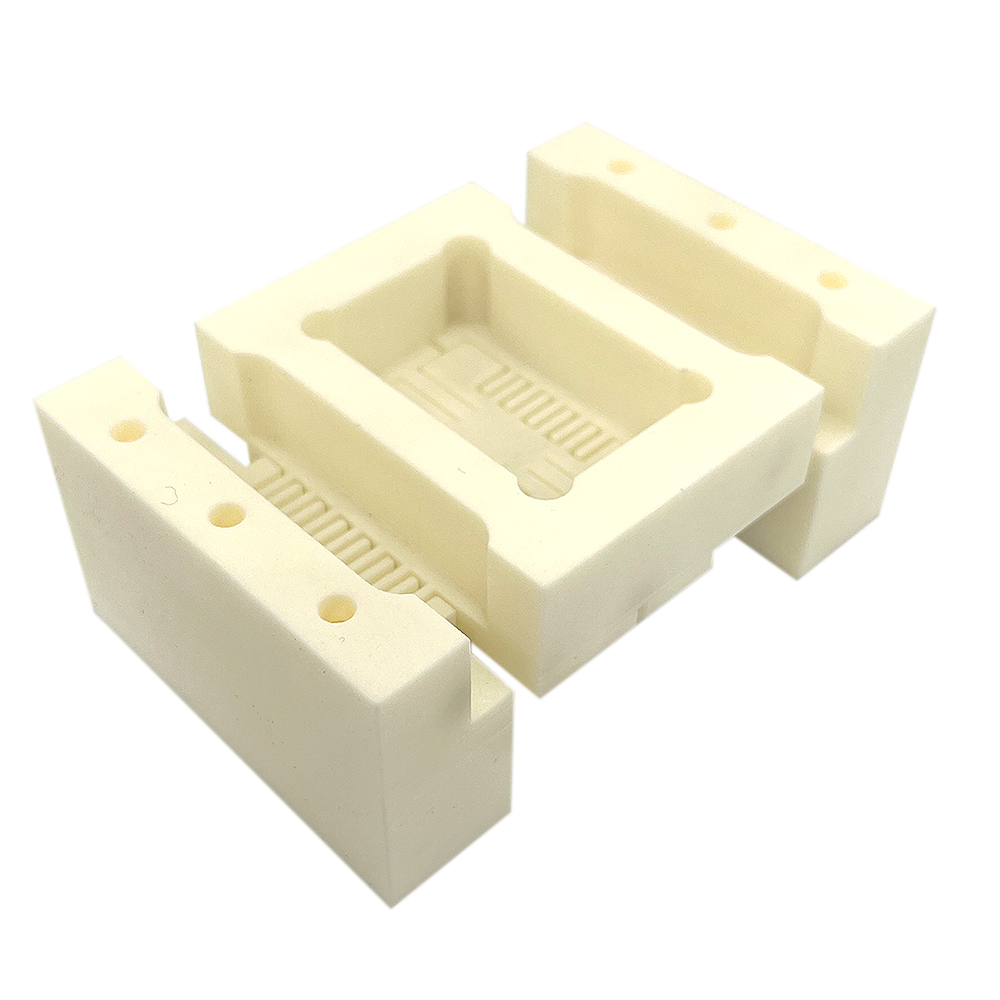

SLS machines and materials

We have an impressive range of machinery with various SLS printers for projects of every size:

| Dimensions (mm) | Material | Application |

| 200x250x330 | PA12-White | Rapid Manufacturing and Medical applications |

| 540x540x840 | PA12-White/yellow | Rapid Manufacturing and Functional testing |

| 540x540x840 | PA12-GF30 | Rapid Manufacturing, Consumer Products, Automotive |

| 540x540x840 | PA12 FR-black | UL-V0 material for Rapid Manufacturing and prototyping |

Mechanical properties of SLS materials

The material properties of SLS 3D printed objects offer excellent performance for functional applications:

- Tensile strength (ASTM D638): 48 MPa for standard PA12, up to 60 MPa for glass-fibre reinforced variants

- Elongation at break (ASTM D638): 18% for PA12, allowing for flexible applications

- Flexural strength (ASTM D790): 65 MPa, ideal for structural components

- IZOD Impact (ASTM D256): 53 J/m for excellent impact resistance

- HDT at 0.455 MPa (ASTM D648): Temperature resistance up to 95°C

Why choose our SLS print service?

Almost 28 years of experience and expertise

As one of the first 3D print service companies in Europe, we have unparalleled expertise in selective laser sintering technology. We understand all possibilities and limitations, allowing us to always provide the best advice for your specific application.

Honest and reliable advice

With our strategic location in the Netherlands, VRT serves clients throughout Europe with rapid delivery times and localised service. Our multilingual team supports projects from various European countries, providing the same high-quality SLS 3D printing services regardless of borders. European businesses choose us for our combination of competitive pricing, exceptional quality, and the convenience of working with a partner who understands regional requirements and standards.

Complete service from design to finishing

Beyond printing, we offer comprehensive services covering all aspects of product realisation. We provide professional finishing and painting according to specifications, produce small series, perform additional processes such as milling from plastics, and support injection moulding with low mould investments. This end-to-end approach enables you to go from concept to final product with just one reliable partner.

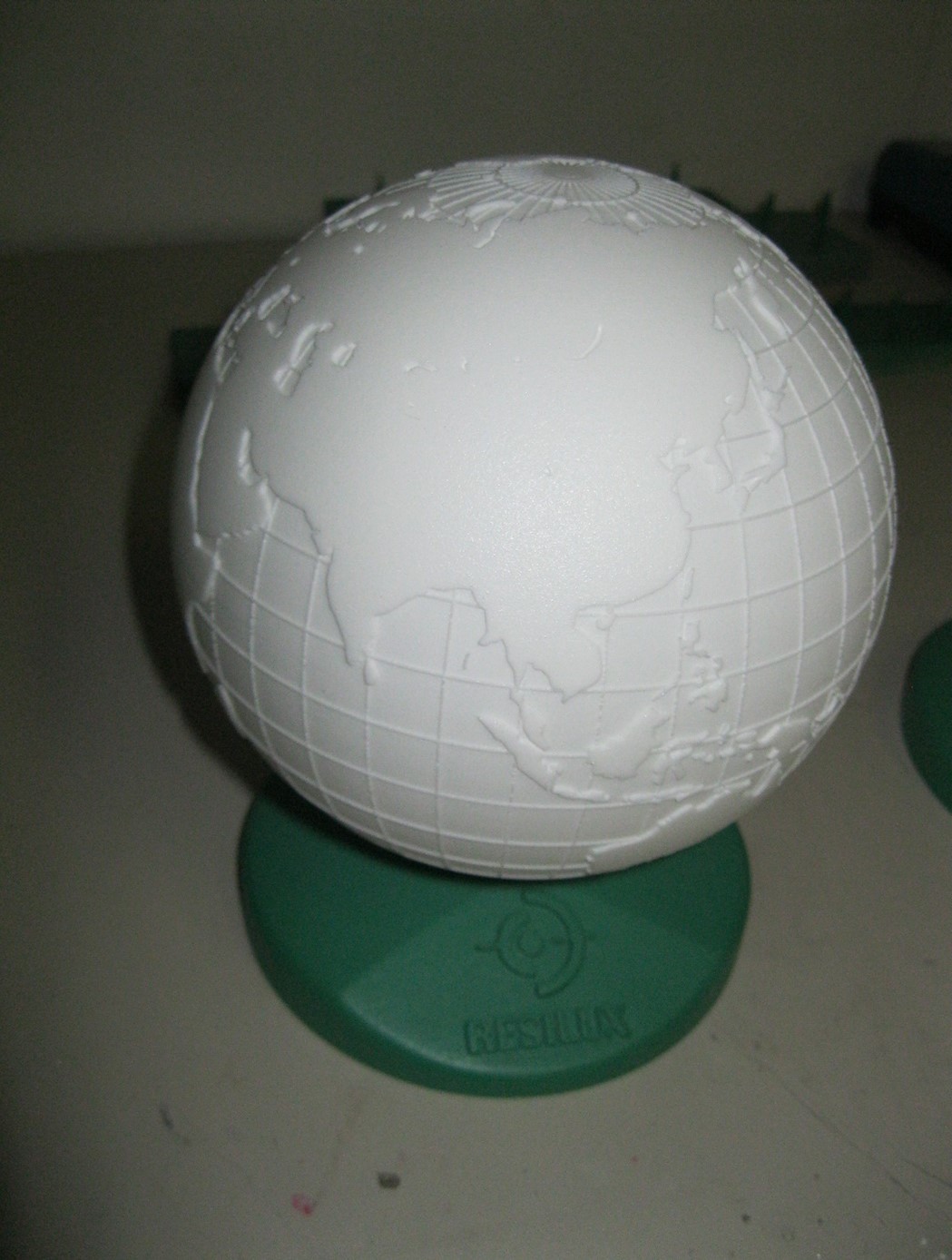

Reliable partner for presentation models

We regularly deliver high-quality exhibition and presentation models that perfectly represent your product or concept. Thanks to the excellent finishing possibilities of our SLS technology, we can produce models that are not only functional but also visually impressive. Our presentation models are often used at product launches, exhibitions, and investor presentations.

Application areas for SLS 3D printing

SLS technology is particularly suitable for various applications:

- Functional prototypes with excellent mechanical properties

- End-user products for small to medium-sized series

- Complex assemblies printed in one piece

- Lightweight structures with internal geometries

- Aerospace components requiring high strength at low weight

- Automotive parts that need to be heat-resistant and durable

- Medical applications with CE-certified materials

- Consumer products combining durability and aesthetics

Contact us for your project

Would you like to know more about our SLS print service or do you have a project you'd like to discuss? Contact us for a free consultation. As a European service provider, we respond quickly, offer flexible solutions, and deliver efficiently across the continent.

Discover why leading companies throughout Europe have trusted our SLS 3D printing expertise for nearly 28 years. Choose quality, experience, and reliability.

Adress

Venture Rapid Technologies B.V.

Ambachtsweg 4, 5683 CD

Best, North Brabant

Send us a message

info@vrt.nl

Call us

+31 499 330774