venture rapid technologies

Rapid Prototyping – van idee naar prototype in recordtijd

Venture Rapid Technologies is dé specialist in rapid prototyping in Nederland. Met bijna 28 jaar ervaring zetten wij uw ontwerp razendsnel om in een functioneel prototype of eindproduct. Onze geavanceerde rapid prototyping apparatuur en expertise in diverse prototyping technieken maken ons de ideale partner voor zowel eenvoudige als complexe projecten, of u nu een plastic prototype, metaal prototype of functioneel model nodig heeft.

8000+

Producten

600+

Klanten

Expertise in industriële modellen

Waarom kiezen voor Rapid prototyping bij VRT?

Rapid Prototyping biedt een revolutionaire benadering voor productontwikkeling. Door gebruik van additieve en subtractieve productietechnieken kunnen wij uw prototype ontwikkeling versnellen en optimaliseren. Het Rapid Prototyping proces bij VRT is volledig gericht op kwaliteit, snelheid en kostenefficiëntie.

Versnelde Ontwikkeling

Kostenefficiënt

Ontwerpvrijheid

Iteratief Proces

Alles onder één dak

Ontdek onze Rapid Prototyping diensten

FDM (Fused Deposition Modeling)

Robuuste prints in technische materialen voor functionele toepassingen. Kosteneffectief voor grotere modellen en ideaal voor prototypes die tegen een stootje kunnen.

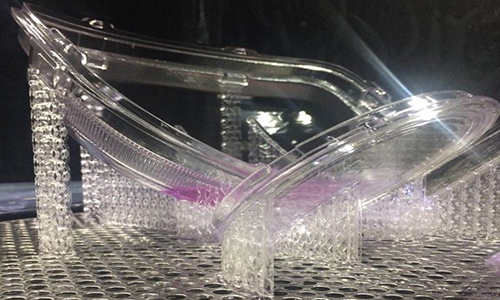

SLA (Stereolithografie)

Superieure detaillering en gladde oppervlaktes dankzij onze industriële UV-laser technologie. Perfect voor complexe prototypes en presentatiemodellen die een hoogwaardige uitstraling vereisen.

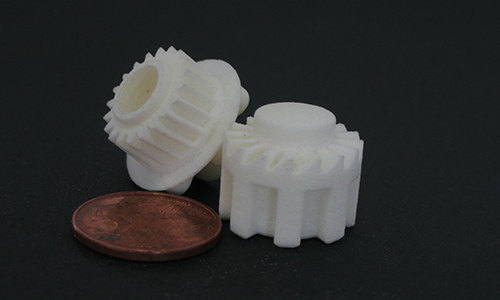

SLS (Selective Laser Sintering)

Sterke, functionele modellen perfect voor prototypes en kleine series. Deze techniek biedt uitstekende mechanische eigenschappen en is ideaal voor eindproducten en testmodellen.

Vacuümgieten

Kleine series tot 50 stuks zijn mogelijk. We maken eerst 3D-geprinte masters als basis voor siliconenmatrijzen, waarmee we vervolgens PUR-producten voor u gieten.

Spuitgieten

Professionele productie met lage matrijsinvesteringen. Door slimme matrijsconcepten maken we serieproductie bereikbaar voor elk budget.

CNC Frezen

Precisiebewerking van kunststof onderdelen met nauwe toleranties. Perfect voor zowel enkelstuks als aanvulling op andere technieken.

Modelmakerij

Vakkundige afwerking en assemblage volgens uw specificaties. Met bijna 30 jaar ervaring zorgen we voor presentatiemodellen van het hoogste niveau.

3D-printen

Geavanceerde printtechnieken voor hoogwaardige resultaten, uitgevoerd op industriële machines die een consistent hoge kwaliteit garanderen.

Rapid Prototyping toepassingen & voordelen

Rapid Prototyping is onmisbaar geworden in talrijke sectoren waaronder automotive, medische technologie, consumentenproducten en industriële apparatuur. De betekenis van Rapid Prototyping gaat verder dan alleen het maken van modellen; het is een essentiële methodiek om ontwikkelingsrisico’s te verminderen, time-to-market te verkorten en productkwaliteit te verhogen.

In ons Rapid Prototyping lab combineren we verschillende Rapid Prototyping methodes om de beste resultaten voor uw specifieke toepassing te realiseren. Van conceptuele modellen tot functionele prototypes in plastic of metaal, en van enkele stuks tot kleine series – wij bieden de optimale oplossing.

De belangrijkste voordelen van Rapid Prototyping:

- Versnelde productontwikkeling en marktintroductie

- Vroegtijdige detectie en correctie van ontwerpfouten

- Betere communicatie tussen ontwikkelaars, producenten en eindgebruikers

- Mogelijkheid om meerdere ontwerpiteraties te testen tegen lage kosten

- Reductie van ontwikkelingsrisico’s vóór grote investeringen

- Naadloze overgang van prototype naar serieproductie

Het complete Rapid Prototyping proces

Rapid Prototyping bij Venture Rapid Technologies volgt een gestructureerd proces dat optimale resultaten garandeert:

1. Ontwerpfase

Alles begint met uw idee. Of u nu een volledig uitgewerkt 3D-model heeft of slechts een schets – onze engineers helpen u met de vertaling naar een maakbaar ontwerp. Waar nodig optimaliseren we uw ontwerp voor het gekozen Rapid Prototyping proces, rekening houdend met materiaalspecificaties en functionele vereisten.

2. Techniek selectie

Elke Rapid Prototype machine heeft specifieke mogelijkheden en beperkingen. Op basis van uw eisen selecteren wij de meest geschikte Rapid Prototyping techniek. Voor fijne details en hoge oppervlaktekwaliteit kan SLA (stereolithografie) de beste keuze zijn, terwijl SLS (Selective Laser Sintering) uitblinkt in sterkte en functionaliteit.

3. Materiaal selectie

De keuze van Rapid Prototype materialen is cruciaal voor het succes van uw project. Afhankelijk van de toepassing kunnen we kiezen uit hoogwaardige kunststoffen, metalen of composieten. Elk materiaal biedt specifieke eigenschappen qua sterkte, flexibiliteit, temperatuurbestendigheid en afwerking.

4. Prototyping & productie

Na de voorbereidende fases start het eigenlijke Rapid Prototyping proces. Met geavanceerde 3D print-, vacuümgiet- of CNC-technieken realiseren we uw prototype exact volgens specificaties. Voor grotere series implementeren we efficiënte productiemethoden zoals spuitgieten.

5. Afwerking & kwaliteitscontrole

Elk prototype ondergaat een zorgvuldige nabewerking en kwaliteitscontrole. Afhankelijk van uw wensen kunnen we het oppervlak polijsten, kleuren, lakken of andere afwerkingen toepassen. Dimensionale controles garanderen maatvastheid en functionele tests valideren de prestaties.

Rapid Prototyping technieken die wij aanbieden

Bij VRT zetten we verschillende Rapid Prototyping technieken in om aan uw specifieke vereisten te voldoen:

Additive Manufacturing (3D Printen)

De synergie tussen additive manufacturing en Rapid Prototyping vormt de kern van moderne productontwikkeling. Met onze geavanceerde 3D printers realiseren we complexe geometrieën die met traditionele methoden onmogelijk te fabriceren zijn. Van hoogwaardige SLA-prints met micro-details tot robuuste SLS-componenten en functionele FDM-prototypes – wij beheersen het complete spectrum van 3D print technologieën.

Subtractieve Fabricage (CNC)

CNC frezen en draaien complementeren onze additieve technieken. Deze precise methoden zijn ideaal voor prototypes die extreme maatnauwkeurigheid vereisen of gemaakt moeten worden uit specifieke materialen die niet geschikt zijn voor 3D printen. Onze 5-assige CNC-machines kunnen complexe vormen uit zowel kunststof als metaal vervaardigen.

Giettechnieken

Voor kleine series of speciale materiaaleigenschappen bieden we vacuümgieten als effectieve Rapid Prototyping methode. Deze techniek combineert de vrijheid van additieve fabricage met materiaaleigenschappen die dicht bij spuitgietproducten komen, perfect voor functionele prototypes en kleine productieseries.

Rapid Prototyping voor diverse sectoren

Onze Rapid Prototyping diensten bedienen uiteenlopende industrieën, elk met specifieke eisen:

Automotive Rapid Prototyping

In de automotive industrie is snelheid essentieel. Onze Rapid Prototyping technieken versnellen de ontwikkeling van onderdelen, van conceptuele modellen tot functionele componenten voor testen onder reële omstandigheden. We produceren zowel interieuronderdelen als technische componenten met hoge precisie.

Medische sector

Voor medische toepassingen bieden we Rapid Prototyping oplossingen met biocompatibele materialen, geschikt voor anatomische modellen, chirurgische hulpmiddelen en prototypes van medische apparatuur. Onze geavanceerde technieken ondersteunen de strenge eisen van deze sector.

Consumentenproducten

Van elektronicabehuizingen tot huishoudelijke apparaten – Rapid Prototyping verkort de ontwikkelingscyclus van consumentenproducten dramatisch. Wij helpen u bij het snel itereren van ontwerpen en het valideren van uw product voordat u grote investeringen doet.

Industriële toepassingen

Voor industriële machines en apparatuur leveren we functionele prototypes die rigoureus getest kunnen worden. Onze Rapid Prototyping methodes zijn geschikt voor zowel enkelvoudige als samengestelde onderdelen die moeten presteren in veeleisende omgevingen.

HOE WIJ WERKEN

Doelgericht van idee naar realiteit

Uw aanvraag

Heeft u specifieke wensen voor uw model? Wij denken graag met u mee over de beste aanpak.

Om u optimaal van dienst te zijn, ontvangen we graag de volgende gegevens bij uw aanvraag:

✔️ Modelbestanden

✔️ Gewenste productietechniek (indien bekend)

✔️ Mechanische vereisten

✔️ Kleur, afwerking, aantal en levertijd

Twijfelt u over de juiste techniek van Rapid Prototyping? Deel dan de toepassingsvereisten van uw model, zodat wij u kunnen adviseren over de beste oplossing.

Heldere offerte

Binnen 24 uur ontvangt u een gedetailleerde offerte. Kunnen wij niet aan uw wensen voldoen? Dan verbinden we u door met een geschikte partner.

Van start tot levering

Met eigen productiefaciliteiten kunnen we snel schakelen. We regelen alle materialen en zorgen voor professionele afwerking volgens uw specificaties. Snelle levering is mogelijk binnen 2-3 werkdagen (afhankelijk van afmetingen en aantallen).

8k+

Projecten afgerond

Trusted By

600+

FAQ

In-depth antwoorden op veelgestelde vragen

8000+

Producten

600+

Klanten

Wat is de gemiddelde levertijd voor geproduceerde onderdelen?

De levertijd varieert afhankelijk van de complexiteit en het gekozen materiaal, maar doorgaans leveren wij binnen 2 tot 5 werkdagen.

Welke rapid prototyping technieken biedt VRT aan?

Wij bieden diverse 3D-printtechnieken aan, waaronder Stereolithografie (SLA), Selective Laser Sintering (SLS) en Fused Deposition Modeling (FDM). Daarnaast bieden wij spuitgieten, vacuümgieten en CNC frezen aan.

Kan VRT helpen bij het kiezen van de juiste techniek voor mijn project?

Absoluut, ons ervaren team adviseert u graag over de meest geschikte techniek op basis van uw specifieke wensen en vereisten.

Wat zijn de kosten voor een Rapid Prototyping opdracht bij VRT?

De kosten variëren op basis van factoren zoals materiaalkeuze, complexiteit en grootte van het model. Voor een nauwkeurige prijsopgave kunt u contact met ons opnemen of een offerte aanvragen via onze website.

Neem contact op

Heeft u vragen of specifieke wensen rondom Rapid Prototyping? Ons team staat klaar om u te helpen. Vul het onderstaande formulier in, dan nemen wij spoedig contact met u op.

Adres

Venture Rapid Technologies B.V.

Ambachtsweg 4, 5683 CD

Best, Noord-Brabant

Stuur ons een email

Bel ons

Tel: +31 499 330774