Vacuümgieten –

Voordelen van hoogwaardige

vacuümgiet services

Als pionier in de Nederlandse 3D print industrie biedt VRT al bijna 28 jaar lang toonaangevende vacuümgiet services. Wij onderscheiden ons door uitsluitend te werken met industriële apparatuur van hoge kwaliteit, waarmee we kleine series functionele kunststof onderdelen kunnen produceren met uitstekende eigenschappen.

Wat is vacuümgieten?

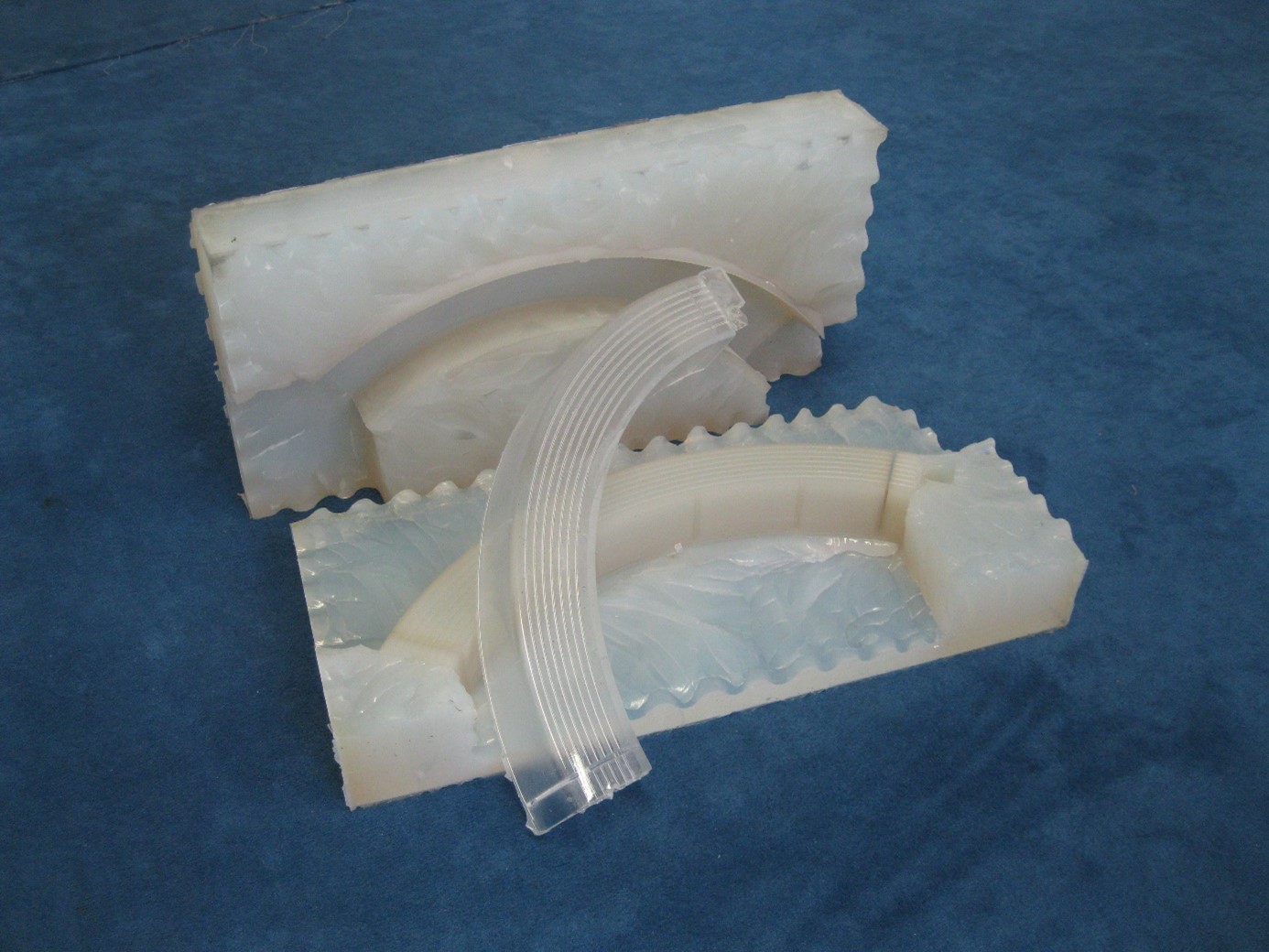

Vacuümgieten is een geavanceerd productieproces waarbij tweecomponenten polyurethaan hars in een siliconen mal wordt gegoten onder vacuüm. Deze techniek behoort tot de meest veelzijdige productiemethoden voor het maken van kleine series functionele kunststof onderdelen. Vacuümgieten onderscheidt zich door de mogelijkheid om hoogwaardige prototypes en kleine productieseries te realiseren met materialen die de eigenschappen van verschillende thermoplastische kunststoffen nabootsen.

Hoe werkt vacuümgieten?

Bij het vacuümgietproces wordt gebruik gemaakt van een siliconen mal en vloeibare polyurethaan harsen. Het proces werkt volgens het volgende principe:

- Eerst wordt een mastermodel gemaakt, meestal via SLA of SLS 3D printtechnologie

- Het mastermodel wordt in een frame geplaatst en omgoten met vloeibare siliconen die uitharden tot een flexibele mal

- Na uitharding wordt de siliconen mal opengemaakt en het mastermodel verwijderd

- De twee helften van de mal worden weer samengevoegd en in een vacuümkamer geplaatst

- Onder vacuüm worden tweecomponenten polyurethaan harsen gemengd en in de mal gegoten

- Het vacuüm verwijdert luchtbellen uit zowel de mal als het harsmateriaal

- Na uitharding (typisch 30-60 minuten) wordt het onderdeel uit de mal gehaald

- De mal kan tot ongeveer 25 keer worden hergebruikt voor dezelfde onderdelen

Doordat het proces onder vacuüm plaatsvindt, worden luchtbellen effectief verwijderd, wat resulteert in dichte, sterke onderdelen zonder interne defecten.

Voordelen van vacuümgieten

Vacuümgieten onderscheidt zich als een van de meest flexibele en kostenefficiënte productiemethoden voor kleine series hoogwaardige kunststof onderdelen. De techniek blinkt uit in situaties waar een snelle marktintroductie of testfase essentieel is, zonder grote financiële investeringen. De economische voordelen zijn direct merkbaar: siliconen mallen zijn aanzienlijk goedkoper dan metalen spuitgietmatrijzen, waardoor de startkosten laag blijven. Bovendien verloopt het gehele proces van mastermodel naar eerste functionele onderdelen in slechts 3-5 werkdagen – een fractie van de tijd die andere productiemethoden vereisen.

De belangrijkste voordelen van onze vacuümgiet service zijn:

- Breed scala aan materialen – Van flexibele rubberachtige compounds tot stijve, hittebestendige harsen die ABS, PC, PP of POM nabootsen

- Uitstekende detailweergave – Nauwkeurige reproductie van complexe details, texturen en zelfs kleine gravures

- Ontwerpcomplexiteit zonder beperkingen – Geschikt voor onderdelen met ondersnijdingen en ingewikkelde geometrieën die met andere technieken moeilijk te realiseren zijn

Daarnaast biedt vacuümgieten uitgebreide mogelijkheden voor aanpassing. De pigmenteerbare harsen zijn beschikbaar in diverse basiskleuren, en we kunnen ook werken met functionele materialen zoals V-0 vlamvertragende en FDA-goedgekeurde harsen voor specifieke toepassingen. Een bijzonder praktisch voordeel is de mogelijkheid om verschillende harsen in dezelfde siliconen mal te gieten, waardoor u kostenefficiënt kunt experimenteren met materiaalvariaties.

Wat zijn beperkingen van vacuümgieten?

Hoewel vacuümgieten vele voordelen biedt, kent de techniek ook enkele beperkingen:

- Beperkte mallevensduur: Maximaal ongeveer 25 stuks per siliconen mal

- Nauwkeurigheid: Niet zo precies als spuitgieten voor maatvoering

- Nabewerking nodig: Elk gegoten onderdeel vereist enige handmatige afwerking

- Speciale kleuren: Vereisen vaak lakken of andere nabewerkingen

- Seriegrootte: Economisch haalbaar tot circa 25-50 stuks; voor grotere aantallen is spuitgieten vaak voordeliger

Vacuümgieten versus andere technieken

Vacuümgieten versus spuitgieten

Vacuümgieten onderscheidt zich van spuitgieten door aanzienlijk lagere maalinvesteringen, waardoor het een economisch aantrekkelijkere optie is voor kleine productiereeksen. Waar een spuitgietmatrijs al snel duizenden euro’s kost, blijven de kosten voor een siliconen mal voor vacuümgieten beperkt. Een ander belangrijk voordeel is de snellere doorlooptijd; vacuümgegoten onderdelen kunnen binnen enkele dagen gerealiseerd worden, terwijl spuitgieten doorgaans weken vergt voor de eerste productie. Spuitgieten wint echter terrein bij grotere productieseries van meer dan 100 stuks, waar de initiële investeringen terugverdiend worden door lagere kostprijs per onderdeel. Ook biedt spuitgieten een breder scala aan materiaalmogelijkheden, terwijl vacuümgieten beperkt blijft tot polyurethaan harsen die thermoplastische eigenschappen nabootsen.

Vacuümgieten versus vacuümvormen

Wanneer we vacuümgieten vergelijken met vacuümvormen, zien we dat vacuümgieten duidelijke voordelen biedt voor complexe geometrieën. Vacuümgieten maakt het mogelijk om interne kenmerken en ingewikkelde structuren te realiseren die met vacuümvormen niet haalbaar zijn. Een ander significant voordeel is dat vacuümgegoten producten een consistente en uniforme wanddikte hebben, terwijl vacuümgevormde producten vaak dunner worden op bepaalde plekken. Qua materiaalvariatie biedt vacuümgieten ook meer flexibiliteit; diverse polyurethaan harsen kunnen verschillende mechanische, thermische en optische eigenschappen simuleren. Vacuümvormen heeft daarentegen zijn eigen voordelen, met name voor grote, dunwandige onderdelen zoals behuizingen of verpakkingen, waar de snelheid en kostenefficiëntie van het proces tot zijn recht komen.

Vacuümgiet machines en materialen

Wij beschikken over moderne vacuümgietapparatuur voor projecten van elke omvang:

| Afmetingen (mm) | Materiaal | Toepassing |

| 50 0x450x500 | VRT-Flexible | Flexibele rubberachtige delen voor kleine series, pilotseries of functionele tests |

| 500x450x500 | VRT-ABS-like | ABS-achtige delen voor kleine series, pilotseries of functionele tests |

| 500x450x500 | VRT-PP/HDPE-like | PP/HDPE-achtige delen voor kleine series of functionele tests |

| 500x450x500 | VRT-POM/PA-like | POM of PA-achtige delen voor kleine series of functionele tests |

| 500x450x500 | VRT-PC-like | PC-achtige delen voor translucente of transparante onderdelen |

Mechanische eigenschappen van vacuümgiet materialen

De materiaaleigenschappen van vacuümgegoten onderdelen variëren afhankelijk van de gebruikte hars:

- Treksterkte: Variërend van 30 tot 75 MPa, afhankelijk van het materiaaltype

- Rek bij breuk: Van 3% voor stijve materialen tot 350% voor flexibele varianten

- Hardheid: Van Shore A25 (zeer flexibel) tot Shore D85 (zeer hard)

- Temperatuurbestendigheid: Van 60°C tot 140°C, afhankelijk van het materiaaltype

- Impact weerstand: Van bros tot zeer taai, afhankelijk van het gekozen materiaal

Dankzij deze diversiteit kunnen we materialen selecteren die perfect aansluiten bij de functionele eisen van uw specifieke toepassing.

Waarom kiezen voor onze vacuümgiet service?

Bijna 28 jaar ervaring en expertise

Als één van de pioniers in de Nederlandse rapid prototyping industrie hebben wij ongeëvenaarde expertise in vacuümgiettechnologie. Wij kennen alle mogelijkheden en beperkingen, waardoor wij altijd het beste advies kunnen geven voor uw specifieke toepassing.

Eerlijk en betrouwbaar advies

Wij verkopen geen loze beloften. Onze adviseurs geven eerlijk advies over wat wel en niet mogelijk is met vacuümgieten, inclusief de voor- en nadelen voor uw specifieke project. Door deze transparante aanpak vermijden we teleurstellingen en zorgen we ervoor dat u realistische verwachtingen heeft van het eindresultaat.

Complete service van ontwerp tot afwerking

Naast het vacuümgieten bieden wij een uitgebreide dienstverlening die alle aspecten van productrealisatie omvat. We verzorgen professionele afwerking en lakken volgens specificatie, produceren kleine series, voeren aanvullende bewerkingen uit, en ondersteunen bij de transitie naar spuitgieten met lage matrijsinvesteringen wanneer grotere volumes nodig zijn. Deze end-to-end aanpak stelt u in staat om van concept naar eindproduct te gaan met slechts één betrouwbare partner.

Toepassingsgebieden voor vacuümgieten

Vacuümgiettechnologie is bijzonder geschikt voor diverse toepassingen:

- Functionele prototypes met materiaaleigenschappen die het eindproduct nabootsen

- Kleine productieseries van 5-25 stuks met consistent hoge kwaliteit

- Sieraad- en juweliersindustrie voor precieze en gedetailleerde modellen

- Medische hulpmiddelen met biocompatibele FDA-goedgekeurde materialen

- Consumentenproducten voor marktvalidatie vóór grote investeringen

- Kunstwerken en beeldende kunst met hoogwaardige afwerking

- Mastermodellen voor andere productieprocessen zoals metaalgieten

- Design prototypes voor visuele evaluatie en gebruikerstests

Neem contact op voor uw project

Wilt u meer weten over onze vacuümgiet service of heeft u een project dat u wilt bespreken? Neem contact met ons op voor een vrijblijvend adviesgesprek. Als Nederlandse dienstverlener reageren wij snel, denken flexibel mee en leveren wij lokaal met korte lijnen.

Ontdek waarom toonaangevende bedrijven al bijna 28 jaar vertrouwen op onze vacuümgiet expertise. Kies voor kwaliteit, ervaring en betrouwbaarheid bij Venture Rapid Technologies.

Adres

Venture Rapid Technologies B.V.

Ambachtsweg 4, 5683 CD

Best, Noord-Brabant

Stuur ons een email

info@vrt.nl

Bel ons

Tel: +31 499 330774